Hi guys!

I am

posting all available material on the winding machine. This is the second version of the machine.

The first one worked for 10 years without any problems and now I wanted to

improve something. Namely, to replace the motors and a little rewrite the software.

The stepper motor remains on the stacker, but now it is not Chinese junk, but a

decent five-phase Japanese motor from Oriental Motor AR series. On the coil

drive is installed servo motor Panasonic Minas A5 200W and rated torque of

0.64N.m (maximum torque of 1.92N.m). All this stuff through a 4 to 1 gearbox, a

pair of gears with 100/25 teeth and a 15mm wide toothed belt (HDT 3M). With this modernization I got rid of

unnecessary noise, and the noise was pretty decent because of the rotation of

the coil by a stepper motor through a pair of metal gears with a reduction of

about 3 to 1.

A few

words on my understanding of winding organization. You need to be able to wind

one layer and count these layers. Everything else is highly secondary. As for

the mechanics itself, it should be convenient to install/remove spools, turn

them over and have maximum access to the spool. That is, the spool should be as

close to the operator as possible, the laying unit behind the spool, but not in

front of it. The headstock itself with controls can be either on the left or on

the right, as it is more convenient. I prefer the right side. Manual control of

the stacker and spool, for example, for initial positioning, only through an

encoder (MPG), as in CNC machine consoles. Other options, like buttons, are not

convenient, but we are not talking about industrial equipment, in which the

winding program is written and tested by a special person, and the operator

only charges the wire, insulation, etc. How to enter data ? It is clear that

the most convenient option is a numeric keypad, which is realized. Another very

important control organ is the coil speed regulator. It is realized by means of

potentiometer. It also has a function - full stop. For this purpose it is

enough to turn it to the minimum position.

I will

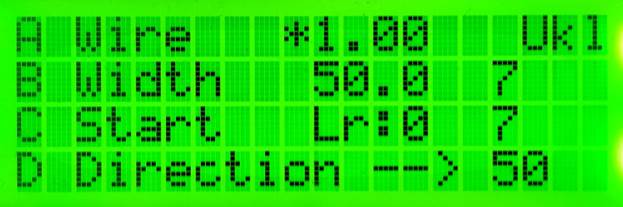

describe the logic of the software. Indication is realized through LCD 20x4.

The menu is one-level. Keyboard 4x4, realized long and short pressing of

buttons. Input of wire diameter up to the second decimal place (1,23mm, max.

9,99mm). Winding width input up to the first decimal place, maximum value

999.9mm. Stacker screw with a pitch of 5mm per revolution. Stacker stepper

motor 5000 pulses per revolution, which allows to realize simple, up to

0.001mm, calculations without error. The result is 1000 pulses per 1mm, which

gives 1/1000=0.001mm per step. For one revolution of the coil the stacker makes

10 shifts by 1/10 of the wire diameter. For example: a 1.23mm diameter wire

will be stacked in ten 1.23*1000/10=123 pulses movements. A 100p/r incremental encoder is mounted on

the coil shaft. Each pulse calls the external interrupt handler, which counts

turns and on each tenth pulse calls the step() function to send to the stacker

a pack of pulses in the amount of 1/10 of the total. At every hundredth pulse

the number of turns is added or subtracted.

The number of turns in a layer is calculated as the winding width

divided by the wire diameter and rounded down. There is an error here, which

can be taken into account at the end of each layer. The option is disabled by

default. The stacker carriage runs along the winding width, which is calculated

based on the number of turns. At the

same time the function of carriage return to the initial position and back is

realized. It is convenient if you wind layers from one cheek. If necessary, the

error compensation can be enabled from the keyboard, then the carriage will

return to the calculated winding width plus the error, i.e. to the entered

winding width value. As a result, it turns out that we enter only winding width

and winding pitch (wire diameter) from the keyboard. Since winding is still not

a precise thread cutting on a lathe and the first winding gives filling of the

layer in width not by one diameter, but by two, plus there are winding variants

with and without indentation, then by varying these two parameters you can

choose the desired one.

Short button press description:

"A" - when pressed, the previous

value of wire diameter (pitch) is reset to zero. Enter the new value from the numeric keypad

in the following way: to enter 1.23mm, press 123. For 0.23mm enter 023. For

0.05mm enter 005.

"B" - when pressed, the previous

winding width value is reset to zero.

Enter the new value from the numeric keypad as follows: to enter 123mm,

press 123. To enter 123.4mm, press 1234. For 12.3mm enter 0123. For 1.2mm enter

0012. For 0.2mm, enter 0002.

"C" - is the start/stop (pause) button

of the coil drive motor. Active only if the values of wire diameter and winding

width are entered. The calculated number of turns in the layer is greater than

zero.

"D" - changes the direction of

movement of the stacker carriage. The display is indicated by arrows.

"*" - selection of coil or stacker

for manual control via MPG encoder.

"#" - reset the number of wound turns

in the layer. After completing the layer winding, if the counter is not reset,

it will be prohibited to start the coil drive (button "C") When the

counter is reset, the variable "cont" is reset. This means that the reset

memorizes the position of the spool shaft, from which the counting of the

number of complete turns will start. Convenient if you need to wind on both

sides of the frame.

Description of the long button press:

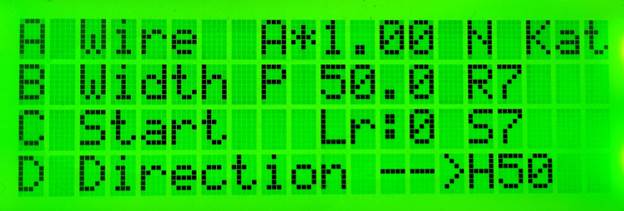

"A" - activation of the Non Stop

mode. When the mode is activated, the letter "N" appears on the

display. In this mode, winding in automatic mode takes place. When the layer is

completed, the layer turns counter is reset and the carriage changes the

direction of movement. The machine stops only manually, e.g. when the total

coil count reaches the desired value or when the coil frame is filled with

wire.

"B" - activation of error

compensation at the end of each layer. When the mode is activated, the letter

"P" appears on the display.

"C" - deactivation of the

"Servo-On" signal of the coil drive. Display "S". Active at

zero value of wire diameter or winding width. The mode is necessary for manual

(by the shaft) rotation of the coil frame. The necessity of the mode is

debatable, but let it be.

"D" - returns the carriage to the

initial position after winding the layer. Since the distance calculation is

based on the winding width, the carriage will return to the beginning of

winding only after the layer winding is finished and the error is taken into

account. The error accounting is disabled by default.

"0" - High speed mode of the spool

shaft drive. Indication "H" on the display. In low speed mode, the

maximum spool speed is 7,5rp.sec, in high speed mode it is 15rp.sec (450 or 900 rpm).

"1" - Enable/disable slowdown at the

beginning and end of layer in Non Stop mode and only slowdown at the end of

layer for Auto mode. Indication "A" on the display when the mode is

deactivated. Variable "ACC" in the program code. It is specified as the number of turns at the beginning and end of the layer that will be wound at a reduced speed. The value of the variable also

depends on the entered wire diameter. In the main code of the program all this

can be changed to suit yourself. How

many times to reduce the speed can be set in the code of the generator, which

is made on the additional board Arduino Nano. There you can also set the speed

modes and modes of acceleration/deceleration of the coil shaft.

"*" - turns on the reverse mode.

Option for reverse wire winding (for bad layers). "R" indication. At

non-zero values of pitch and width, starts by pressing "C". It is

desirable to set the speed adjustment potentiometer to the minimum position

beforehand and winding is carried out with it.

A small example of layer winding:

Press

"A" and enter the wire diameter/step. Then press "B" and

enter the winding width. Press "*" to select the stacker or spool

control mode (Ukl / Kat). Use the MPG encoder to adjust the carriage to the

desired cheek, to the beginning of the winding. Switch manual control mode

"*" to spool control (indication "Kat") and set the spool

to the start position. Press "#" to reset the variable

"cont" and memorize the coil position for counting complete turns. Then there are two options. First, we can

manually rotate the MPG and watch how the first, initial turns of the layer are

laid, while adjusting the position of the stacker carriage. The second, we can start the coil drive motor

by pressing "C" and by adjusting the rotation speed with the

potentiometer we can lay the first turns.

You can even do this, twist the potentiometer to zero, press

"C" and by turning the potentiometer control the start of rotation

from the lowest speed. When the winding of the layer is completed (the number

of winded turns is equal to the calculated number of turns), in case the

winding was done by switching on the drive motor, it will be automatically

stopped and the direction of the stacker movement will be automatically

reversed. In case of a manual drive, the

numbers of windings must be monitored. Everything else is exactly the same as

with the motor. If you want to continue winding the next layer from the same

cheek, press long "D", the carriage will return to the initial

position. Further by means of MPG we either change the position of the bobbin

or not. The last action is to reset the number of windings in the layer

"#" with a short press. Or long press, all values, current windings

in the layer, total/all wound windings and number of layers will be reset.

A little

technical details of the implementation. So, as I wrote earlier, at 1000 pulses

per 1 millimeter of the stacker everything is considered very well, but there

is still a moment, and how it all has time? I will write at once that even at high speed (15 rev/sec) the stacker

has time to a diameter of 1.5 mm, which is with a large margin and already goes

beyond reason. And the stacker has time to work off a pack of pulses with the

value of 1/10 of the necessary for one step, in the interval of 3.6 degrees of

coil revolution. That is, in the time interval between two neighboring pulses

of the coil shaft encoder, which, let me remind you, is 100p/r. The whole

processing fits into just one interrupt call of the step() function.

The figures are as follows:

The

interval between two neighboring encoder pulses at 15 r/sec is 1/(15*100) =

667µs. The execution time of one clock cycle for the stacker is about 4.5µs. In

the code it is two 2µs delays plus some execution time, about 0.5µs. Let's do

the math for a wire diameter of 1mm. 1/10 pack equals 100 pulses. 100*4,5 =

450µs, which is within the 667µs interval with a margin. If the motor of the stacker does not allow

you to work so quickly with it, you can apply encoder 50p/r that will halve the

requirements, well, or make a disk encoder for 10 positions, which will

increase the time by 10 times. In reality, it is unlikely to need all this, as

thick wire is not necessary to wind quickly, and on a thin wire pulse pack

short. In the archive there is an excel file with a table for calculating

intervals.

For

example, just in auto mode, the slowing down of rotation occurs a few turns

before the end of the layer winding. The number of turns depends on the wire

diameter and the selected speed mode. In Non Stop mode the slowdown occurs both

at the beginning and at the end of the layer. The mode is enabled by default,

but it can be deactivated from the keypad.

ws-amp.eu